“My boat is just eight years old but it is damp and stained, what can I do?”

QUESTION – I’m looking for some advice on the issues I’ve had with my boat since the day I bought it. It’s eight years old and was brand new when I bought it, but has had countless build quality issues with many leaks from day one, and in more recent times, all my woodwork staining throughout. I’ve always suspected I’ve had a problem with damp on board due to the amount of mould and mildew on the curtains, but I didn’t realise just how widespread the issue was until more recently.

The photos show the staining and split in the roof. The staining is on most of the main panels around the boat, and it started when the boat was just three to four years old.

The boat builders themselves have admitted the boat does have an issue with damp, but have not accepted liability and blamed it on bad ventilation. They also blamed the staining on the bedroom panel on the mattress itself – which I know is not true. On a cold winter’s night, I can reach behind me and feel the wall is wet, the bedclothes are damp down the side of the wall, and when I switch the lights on, I can see the moisture glistening on the wall – so I know there’s damp coming through the woodwork. The same thing is

now happening inside the wardrobe, the opposite bedroom wall, and on numerous other panels around the boat where there’s obviously no mattress causing it to happen.

I know that it’s normal to get condensation forming on the steel shell of the boat, especially during the winter months, but is it supposed to come through the interior woodwork like this?

I’m always conscious of properly heating and ventilating the boat, but I’m still seeing these issues despite:

1 Heating the boat with the log burning stove 24/7 throughout the winter months

2 Using an ecofan on the stove to circulate the cabin air

3 Opening the windows to ventilate during the summer months

4 Using two dehumidifiers at the front end of the boat

5 Using the central heating twice a day during the winter months

In addition, the boat has six mushroom vents and two louvred vents at either end.

Having looked around the internet, I can’t seem to find any other pictures of anyone else’s boat that looks like this. So what I’d like to know is:

1 How common is this sort of thing?

2 What do you think is the most likely cause?

3 What, if anything, can be done to fix this?

What’s really annoying is that I can see the same boat builder selling much older, second-hand versions of the exact same boat, but with none of these woodwork issues and no stains coming through the walls.

Also, during my first winter on board, the woodwork in the ceiling started to crack and split around the light fittings, and I had to have numerous panels replaced as a result. The repairman at the time remarked that it was ‘very unusual’, that he’d only seen this happen on one other boat before, and he couldn’t explain why it was happening on mine. He did acknowledge that the issue was probably temperature-related and since then, I’ve only been able to use dim 20-watt LED bulbs in the ceiling and not the proper halogen bulbs, because it will split the woodwork if I do.

Nick Fisher

ANSWER – TONY REPLIES: Straight away “Opening the windows to ventilate during the summer months” suggests that you may not ventilate enough during the winter. I would keep at least some of my window vents open winter and summer , but maybe only during the day in winter. Some photos do suggest high humidity in the air. I assume that you do not block the BSS vents. Gas cooking, non-flued gas or paraffin heating and simply breathing deposits loads of water vapour into the atmosphere. If your “two dehumidifiers” are passive chemical block types they will have little effect in the cabin of a boat.

You did not send any large area photos but it does not look like window or roof vents leaking behind the lining to me.

First of all do you have a trap in the cabin floor, usually under the back steps or in the bottom of a stern cupboard, that allows you to inspect the accommodation bilge and keep it dry? If not you need to cut one because water under the floor always leads to condensation and damp problems.

Secondly, I wonder about how much insulation you have behind the panels. I have heard of cowboy spray foam jobs that are only a few mm deep rather than the 50mm usually applied.

The photo of the bed and what looks like the inside of a cupboard suggest that dead air, that is air that cannot move about, may be implicated. In the case of the bed dead air may be caused by having covers piled against the cabin side or being breathed/sweated on during sleep. In both cases it suggest cold wood and thus maybe insufficient insulation.

I wonder exactly what sort of varnish has been used. If it was water-based with only a few coats so pinholes were left in the finish it would allow condensation to penetrate the wood from the front and cause discolouration. Maybe the builder did not seal the back of the linings. If so they will need to come off to do that. At the same time you could inspect the insulation for type and thickness.

I fear that you may have to sand all the linings back to plain wood, treat with wood bleach and revarnish with a decent oil based varnish using many coats but don’t do it if you have insufficient insulation. That would just be wasting time and money. If all else fails you may have to resort to sanding the linings down well and painting them with an eggshell type finish oil based paint.

I am not sure what you can do without stripping the boat but I am no paint or woodwork expert. Can you get some switches/plugs off the wall to inspect the insulation? If the boards come down easily I think I would be very tempted to install tightly fitting “slabs” of suitable thickness of Kingspan or Celotex insulation and tape the seams on top of the existing insulation. Fill any gaps in the insulation with aerosol type foam. I would also think about topping it off with the silvered bubble wrap type insulation to form a vapour barrier behind the board.

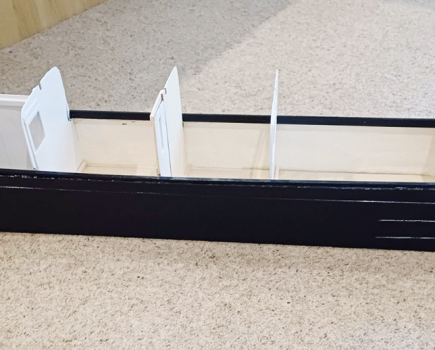

If you look at the crack in the photo you will see three things.

1 The board looks as if it is about 10mm or more thick. This seems very thick for a ceiling that needs to bend to the roof contours.

2 The split seems wider at the top than at the bottom; that suggests to me it may be a stress crack where the board has been forced to bend to the roof profile and has started to crack at its weakest point – where it has been cut away for the light fitting.

3 There is no evidence of a deeper colour caused by heat.

I am not convinced this is heat-related but I feel such fitting is in no way compatible with hot running halogen bulbs. Depending upon the light fitting 12V 50W equivalent LED bulbs seem readily available online and I suspect in shops as well.