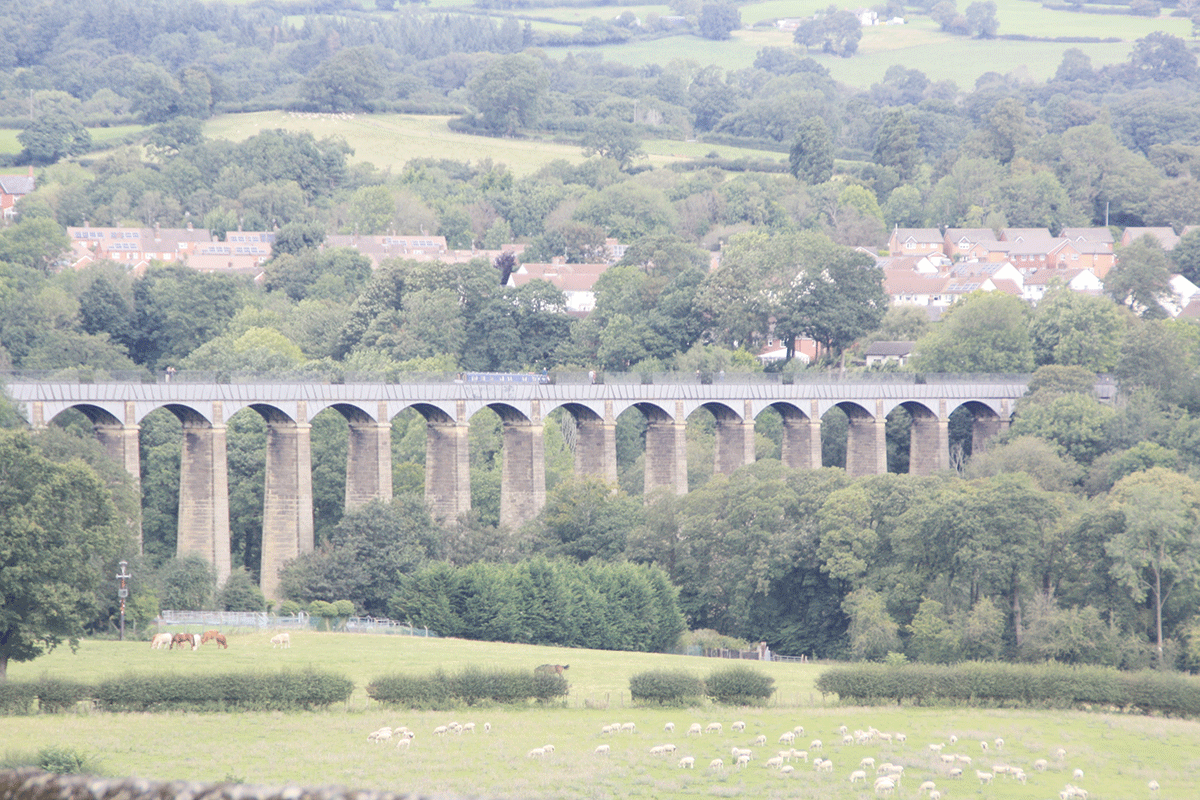

The Pontcysyllte aqueduct has been undergoing maintenance. Martin Ludgate gets an unusual view of the famous structure from inside the drained canal channel.

It’s like a very clever Meccano set”, remarks Ben Fitchford, senior design engineer from the Canal & River Trust. He’s referring to the Pontcysyllte Aqueduct, the most iconic structure from Britain’s canal age, striding boldly across the Dee valley carrying the Llangollen Canal 127 feet above its waters.

In particular he’s answering a question that’s puzzled me for a while. It’s a well-known (if a little worrying to some) feature of the aqueduct that whereas on the towpath side, walkers are protected by a sturdy set of cast iron railings, on the opposite side of the aqueduct there is no protective barrier – just a low metal wall reaching barely a foot above water level between the canal and a very long drop. And yet it has a line of what look like bolt holes along the top of it. Did it once have railings too? Is there any truth in the old story (which I’ve heard more than once) that the original railings rusted away and they couldn’t find anyone brave enough to replace them?

The aqueduct trough drained for work

No, there’s no truth in it at all. There never were any railings. The holes are there simply because – hence the Meccano analogy – both sides of the metal trough were made from the same design of metal plates, and so both of them had bolt holes. And it ties in with another well-known feature of the aqueduct: the trough containing the water extends to the full width of the structure, with the towpath having been built out over the water. This gives it a greater cross-sectional area, meaning that boats aren’t slowed down so much by the restricted channel. And while that must have been a great help to horses pulling loaded narrowboats across the aqueduct, it’s also useful for today’s powered craft, particularly as they make their way westwards against the significant water current which is a result of the canal having been used since the 1950s for carrying drinking water supplies from the River Dee to Cheshire. But right now, it isn’t carrying any water. It’s been drained for inspection and maintenance work, which provides the opportunity for us to don our wellingtons to climb down into the (not quite) empty trough and see first-hand how the towpath structure fits together, and the work that’s taking place on it. And I can see what Ben means about it fitting together like Meccano.

The railings are in 46 sections along the length of the aqueduct, each supported on 12 uprights. These are supported on a series of longitudinal iron beams referred to as ‘ledgers’. Every third one also bears on a crossmember running across underneath the towpath, supporting it via a series of metal plates (made in a slightly ‘dished’ shape to spread the load) on which the towpath surface is laid. And on the outer edge of the towpath, next to the navigable channel, the crossmembers are supported on another line of iron beams running along under the edge of the towpath, which in turn are supported by vertical iron supports bolted to the bottom of the trough, which are diagonally braced to the trough using wrought iron stays (the only wrought iron used in an otherwise cast iron structure).

From our viewpoint, crouched underneath it, it may look like it’s been there since Thomas Telford’s day, but the towpath has seen plenty of changes over the years. In fact for its first 20 years or so from when the aqueduct was complete in 1805, the entire towpath structure was made of timber. Given its exposure to the elements, to the canal water and to wear from passing boats, it would have needed replacing every couple of decades or so (as do wooden lock gates), and in fact it was soon replaced by today’s iron structure (with components built by the same ironworks which had provided the castings for the main aqueduct structure). This in turn underwent refurbishment work over the years, in particular a major programme in the 1890s in which the dished iron plates were replaced, but by the 1950s, lack of maintenance (the canal had been officially abandoned in 1944 and was only being kept open as a water supply channel) meant the railings and towpath were in such a state that the path was shut.

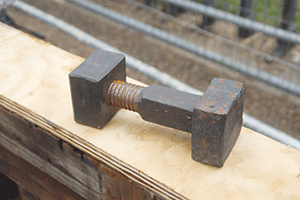

A relic from the earliest days: this iron strap would have secured a wooden block supporting the original timber towpath

Come the 1960s and the revival of the canal for leisure boating, and a nine-month programme of work enabled the towpath to reopen. But rather than replace them like-for-like, the cheaper option was taken of using standard trench sheet piling (the sort you see as bank protection on many canals) in place of the dished iron plates in the towpath. This was less than satisfactory in the long run, and another major refurbishment in 2003-4 (funded by CADW – the Welsh body equivalent to English Heritage – ready for the aqueduct’s 200th anniversary in 2005) saw them replaced with dished plates, while at the same time about 25 percent of the ledgers were replaced. This is the first significant work programme since then, and so far it’s largely a “non-invasive inspection” – gaining access to the drained aqueduct, getting under the towpath and acquiring an understanding of the state of the structure, without doing too much to it for now.

That wasn’t quite the original plan: it had been hoped to replace one of the ledgers which was in poor condition, but there were delays in securing all the necessary permissions – from CADW (it’s an Ancient Monument and a World Heritage Site – “The same as the Taj Mahal”, remarks one of the CRT engineers), the Environment Agency, and the bodies involved in the canal’s drinking water supply function. Arrangements had to be made to maintain this during the de-watering of the canal, which involved pumping water up 120 feet from the river to the canal at the east end of the aqueduct. We were also deprived of the traditional spectacle of the drain plug being opened and the water emptied from the middle of the aqueduct straight into the river below: this is classed a “discharge” rather than a “natural overflow” (like the overflow weirs which take surplus water), and therefore needed special Environment Agency permission which raised concerns about silt content – and so it was easier to just pump it out into the canal on either side.

As a result of the delays, a decision was taken to only do any replacement work if it turned out to be in worse condition than anticipated. In the event, the suspect ledger was in a slightly less bad state than expected, so plans are being made to replace it, along with several more, in a major programme likely to take place during the 2026-27 winter works programme. In the meantime, a number of the joints where the vertical towpath supports are attached to the base of the trough have been found to be somewhat suspect, and have been temporarily braced with clamps and timber blocks pending permanent repair.

“Like Meccano”: One of the 11,000 bolts holding the ironwork together

The towpath work was only one part of this winter’s programme. At the same time, all 11,000 of the large square headed nuts and bolts which hold the main cast iron plates of the trough together have been inspected. Any corroded ones will be replaced; to give some idea, back in 2003-4, some 750 of them were replaced – and they cost £97 each from specialist blacksmiths.

The CRT team tell me working conditions have been ‘interesting’ in the winter weather. High winds can play some interesting tricks, including blowing water off the surface of the canal (before it was drained), or blowing falling rain and snow down underneath the arches then swirling it back up on the other side of the aqueduct. Still, at least most of the work has been done down in the empty trough, where it’s a little more sheltered, and a distant hill-top is a good warning of weather on the way: if it disappears into the clouds, it’s a good time to dive for cover.

There’s a third job taking place – and to see what’s happening, I have to make my way to the very centre of the aqueduct, right above the river. It’s an interesting stroll, trying to avoid tripping over the flanges projecting above the base of the trough where the plates are bolted together. Interestingly, the water depth varies from barely ankle deep to definitely welly-depth, and CRT confirm that not only is the aqueduct not entirely level along its length but it actually moves a little with the expansion and contraction of the 1,000 foot long metal trough between summer and winter.

“Everything including the kitchen sink” – just some of the junk the team found

I can’t help noticing various detritus that’s been lost from boats since the channel was last cleared out. There are various old tyres (how did they get there?), half a kitchen sink (yes, really!), and in what might be seen as the definitive answer to the question of whether to cruise with them ‘up’ or ‘down’, probably more side fenders than I’ve ever seen in one place before. The CRT team tell me it’s produced quite a collection of mobile phones, presumably from people dropping them while trying to take photographs, including a brand new iPhone 15 (still in working order!) – I spot a rather older Nokia from the early 2000s…

And the third job? I mentioned earlier the traditional method of emptying the aqueduct by opening a drain plug in the middle. This (or rather the levers, rods and pivots that operate it) was found to be in need of repairs during the inspection; a CRT team are dismantling it, wire-brushing the rust off, and extracting the remains of a damaged bolt for replacement.

Examining and repairing the linkage that operates the drain plug

If it sounds from the above description like they haven’t done a great deal of actual repair or renovation work, then that’s true. This has very much been a detailed inspection prior to the real work. CRT heritage advisor Mark Somerfield says it “confirmed what they knew” about the general condition, gave them detailed information about the state of the 200-year-old aqueduct, and allowed them to plan for the real work. And there weren’t too many nasty surprises.

I ask him whether there’s any difference of opinion between preservation of heritage and modern engineering practice. He replies that there are decisions to make on what to preserve or restore: you wouldn’t suggest reinstating the wooden towpath from the 1800s, but on the other hand it was the right idea to get rid of the 1960s steel piles and go back to dished metal plates to support the towpath – albeit in galvanised steel rather than cast iron. He sees these as something of an ‘Achilles’ heel’ of the aqueduct – as we’ve seen, it’s got through several sets so far. But he reckons the present set will do half a century or so, and they’re only 20 years into that.

In fact, typically, the way things work is that the engineers come up with a method for repair, and the heritage advisor will advise on it, with a view to both historic integrity and how long-lasting a repair will be. And they’ve now got almost three years for those discussions.

And all being well, by the winter work programme of 2026-27, they reckon they’ll have cleared it with the Environment Agency to open the (restored) plug and empty the trough straight into the Dee, 120 feet below!

Pontcysyllte: the history

What we now know as the Llangollen Canal was originally called the Ellesmere Canal, and was planned as a north-south route from the River Mersey to the River Severn. It would leave the Mersey at what is now Ellesmere Port, head across the Wirral to Chester, then follow the River Dee south westward to serve the ironworks in the Wrexham and Ruabon area. It would then turn and head southeast to meet the Severn at Shrewsbury, with branches to Ellesmere, Whitchurch and Llanymynech.

After some debate about the details of the route, a line following the west bank of the Dee southwest from Chester was chosen, which meant that the canal would then need to cross the river in the Ruabon area as it turned southeast. At the point where it crossed, near Trevor, the canal would be more than 120 feet higher than the river. Crossing it on a masonry aqueduct this height would be unprecedented – Marple Aqueduct, the highest to date, and still under construction at that time, was over 30ft lower. Consideration was given to the alternative of a lower level three-arch masonry structure with flights of locks leading down to it on either side of the valley – with the associated water supply issues. But cast iron was becoming popular in engineering, and would allow a lighter weight structure to be built. The first iron aqueducts had already been built elsewhere (including one at Longden-on-Tern, not far away on the Shrewsbury Canal), and the nearby ironworks could supply the materials.

The canal’s principal engineer William Jessop and resident general agent Thomas Telford (historians still discuss which of them had the greater input, but Telford generally gets the credit) came up with a design which combined 18 stone piers with a superstructure consisting of 19 arches assembled from flanged cast iron plates bolted together, which in turn supported the metal trough (also assembled from flanged iron plates) which formed the canal channel. Some interesting other materials were used: the joints in the cast iron were waterproofed by incorporating lead and layers of Welsh flannel dipped in boiling sugar, while the mortar used in the stonework incorporated ox blood.

Construction began in 1795 and ten years later it was complete, at a cost of £47,018. This was almost ten percent of the entire cost of building the canal. And on that subject, shortage of money combined with other developments on the waterways had led to some radical changes from the canal’s originally planned route. The south eastern length to Shrewsbury was never completed, as the town was by now already served by the Shrewsbury Canal, reducing the Ellesmere Canal’s potential trade. It never got further than a village wharf at Weston Lullingfields. And at the north end, although the line from Ellesmere Port to Chester was built, the difficult and expensive section from there to Trevor was dropped from the plans. Instead, a link to the outside world was created by connecting the Ellesmere and Whitchurch line to the Chester Canal at Hurleston (and in due course all of these canals were united by mergers and takeovers that created the Shropshire Union system).

So by the time the Pontcysyllte was completed, it had gone from being an important link in a Mersey-to-Severn through route to being on a dead-end, just a few hundred yards short of the terminal basins which were linked by horse tramways to the industries of Ruabon. If the canal company had known ten years earlier that this would happen, would they have built the aqueduct at all? Or might they instead have simply extended the tramways to meet the canal on the other side of the valley?

However, having built it, three years later the canal company built the navigable feeder which today forms the last section of the canal leading to Llangollen, and which – through its vital water supply function – guaranteed the survival of this most iconic structure.

As featured in the May 2024 issue of Canal Boat. Buy the issue here

As featured in the May 2024 issue of Canal Boat. Buy the issue here