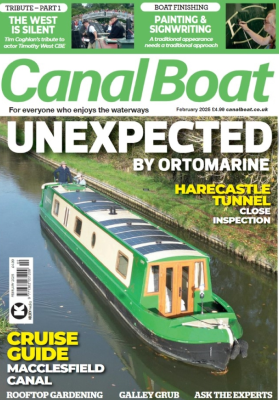

The Riveted Narrowboat Company

Words and images by Martin Ludgate

Standing in a metalwork yard in the Sussex countryside, wearing ear plugs, goggles and safety boots, and wielding something that’s a cross between a power tool and a lethal weapon, I can’t help thinking this is a fairly interesting way to commemorate the passing of a relative.

Then again Toby Omber is a fairly interesting chap. You probably need to be, if you’re in the process of setting up the first all-riveted narrowboat building operation for half a century or so.

It all began when Toby’s mother died a couple of years ago. They’d enjoyed canal boating, and reminiscing about those days was a welcome relief for the family at a sad time. So much so that he decided to do something practical – to build a boat named after his mum. But the more he got into the idea, the more he wanted to do something special – to build a faithful replica of a converted working boat, right down to putting it together using rivets. Not a welded steel boat with ‘stick on’ imitation rivets. No, Toby was going to do it all with real rivets.

Riveting is a simple enough idea. You drill holes in the two pieces that are to be joined together; you heat a rivet (a short piece of metal bar that widens into a ‘head’ at one end) until it’s soft; you put it through the holes; one person supports the head of the rivet; another person holds a metal ‘cup’ over the other end and hammers it until it’s flattened out; as it cools it shrinks and pulls the joint tighter. It sufficed for a century of metal canal boat building, until welding took over between the 1930s and 1950s.

As it happened, the josher (Fellows Morton & Clayton working boat) Lion was out of the water at the time near Milton Keynes; Toby had always had a soft spot for joshers; one thing led to another. Toby found himself heading up there to take photos, make measurements and create templates. The size of the metal hull plates, the rivet positions and sizes were faithfully recorded.

Work began on construction 18 months ago. A few modifications were made. Firstly, a 61-footer would have a greater cruising range and could be easily made by missing out one whole section of hull plates. Secondly, the bottom would be steel, not wood. Thirdly, so would the gunwales. Otherwise there would be no compromises. As Toby puts it: “I’d be working in an awkward corner and think ‘Why not just weld it?’, but I’d know it wasn’t right.”

And so it progressed: sides and bottom; superstructure; the complex stern shape. As it progressed, the project generated considerable interest – well, it’s unusual to build a narrowboat in the Sussex countryside, let alone a riveted one. And as the owner of a metalwork company, Toby began to wonder if there might be some business to be done. “Let’s get it on show at Crick 2012 and see what interest there is,” he thought. So the Riveted Narrowboat Company was born.

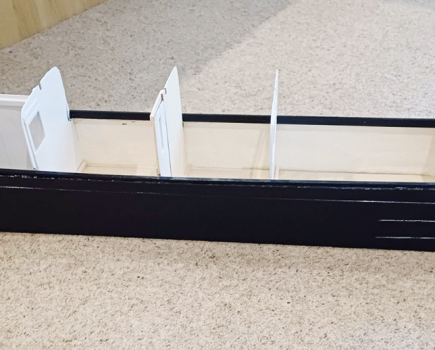

Unfortunately the weather, combined with an upturn in Toby’s regular work, put the 2012 target beyond reach. So it was revised to 2013 and, in the meantime, he started putting together a demonstration trailer. This takes the form of a short section of riveted standard hull and superstructure, complete with engine, to catch people’s attention and to show how a riveted shell goes together.

The upturn in Toby’s regular business slowed work on the boat, but enabled him to expand into the adjacent plot. This was useful when there was another unexpected turn up: Gorse, the last working josher built, came up for sale. Well, actually only half of Gorse – it was cut in two and turned into a pleasure craft when trading ended. This was too good to turn down: the opportunity to turn it back into a full-length boat.

The plan is to cut off the 1960s stern and replace it with a new all-riveted half, bringing the boat back to its original length. A suitably interesting engine has been tracked down: a late Bolinder, which had resided in a Dutch farmyard since the maintenance boat it was installed in was blown up by the retreating Germans in World War II. The aim is to have the boat in the 2014 Braunston historic boat rally.

So the Riveted Narrowboat Company has two craft on the way. But what of the future? Toby would like to build two or three shells a year: will there be the demand? It’s hard to make predictions until the replica makes it to Crick, hopefully in 2013. But Toby believes that there is a possible business plan, and it goes something like this…

It might be an accurate replica, but it hasn’t stuck slavishly to early 20th Century methods. Yes, the bow and stern sections need a lot of labour-intensive manual work. But the straight part of the hull and cabin can be fabricated relatively quickly. It’s formed of three identical ‘bays’ (four on a full-length boat) which can be created (including drilling rivet holes) using modern folding and laser cutting methods – reducing labour and costs. It’s not going to be cheap, so you’ll never buy a budget riveted boat. But Toby reckons that with enthusiasts willing to fork out �40-45,000 for a high quality 61ft shell with replica rivets, some would pay perhaps �50,000 for real ones.

Taking on repair work on historic craft would also help the business. Of course, no-one is going to pay to take their boat to Sussex on a lorry for a couple of patches. But for major work – rebottoming for example – the transport costs could well fall within the spread of prices for the job.

That’s all for the future. Back at the yard, the replica Lion is starting to look like a boat. The classic josher ‘double curve’ bow sections are still to be made (and they aren’t entirely sure how it was done originally) but other than that, the shell looks complete. Except, that is, that the vast majority of rivet holes don’t have any rivets in, making it look like a giant Meccano model.

Toby explains that as you don’t really get a ‘second chance’ with riveting, it makes sense to put the whole boat together first with a relatively small number of nuts and bolts in some of the rivet holes, plus some temporary interior framing which can be adjusted. When they’re sure it’s right, they’ll have a marathon riveting session.

That’s coming up fairly soon. Toby has engaged a team of riveters, who have been doing some trial work. And this is another example of methods moving on a little since Lion was built. I was half expecting something involving heating rivets up in a coal forge and knocking them into shape with a big lump hammer. But that’s not the way modern riveting is done.

Modern riveting? Surely a contradiction? No: although some of their work is in the historic preservation sector – maintaining traction engine boilers, for example – a surprising amount is nothing to do with heritage. Many railway bridges were built when riveting was the norm: repairs often need to be done like-for-like to preserve their integrity.

One of the gang is wearing overalls with a ‘Magnox’ logo, as in Magnox nuclear power stations. Yes, they really are using rivets when decommissioning nuclear stations built 50 years ago, parts of which will need to remain sound for a long time.

So although the job remains the same, the tools have moved on. Hammers gave way to pneumatic rivet guns around the 1930s, and the rivets are now heated in a small gas furnace similar to one that a mobile farrier might use for shoeing horses.

It’s a three-man job. One heats the rivets until they’re the right shade of pale yellow, then grabs one with tongs and puts it in the hole. The second person puts a heavy metal ‘dolly’ on the back and braces himself against it. The third then puts the rivet gun on the front and pulls the trigger. Bang, bang, bang, job done – repeat 5,000 times.

Well, that’s the theory, but as I find out when I’m given a go with the gun, it’s not as easy as these guys make it look. I’m too timid with the first one and it goes cold before I’ve really managed to bash it down hard enough (you don’t get much more than ten seconds from it coming out of the furnace). The second time, I push too hard, it skids off, the riveting head flies off the gun and has to be retrieved. The third one’s going well, but in the pursuit of perfection, I try to hammer it down a little bit more and leave a mark on the metal alongside it. By the fourth one I’m getting better, but I’m also realising that there’s quite an art to it.

Still, there’s something oddly satisfying about this most traditional way of joining metal together. Rather like rebuilding a lock chamber wall one brick at a time, even though you could do it more quickly with plywood shuttering and readymix concrete.

Looking at my attempts, and then at the neat line of rivets put in by Toby’s gang, I won’t give up the day job yet, though…