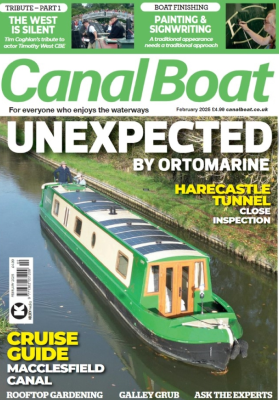

Martin Ludgate visits Toddbrook Reservoir, to see first-hand how repairs to the damage caused by extreme rainfall of summer 2019 are progressing

Gazing down from my vantage point on top of the dam at Toddbrook Reservoir, one of the main suppliers of water to the Peak Forest Canal, I can see what look like two sizeable circular reinforced concrete turrets being constructed in the shadow of the dam. Meanwhile, looking along the dam I can see a huge steel piled structure taking shape at the north end of the dam. Canal & River Trust Project Manager Dilwyn Parry is on hand to explain what these structures are, and how they fit together to form the permanent solution to the problems with the reservoir; problems which manifested themselves dramatically almost exactly five years ago, in a failure which saw local residents evacuated from homes in nearby Whaley Bridge, an emergency airlift of materials by helicopter to stave off further damage, and a rush to pump the reservoir dry.

But first let’s go rather further back in time, to the history of the reservoir. One of four which supply the combined summit level of the Peak Forest and Macclesfield canals (the others are Bosley, Combs and Sutton), Toddbrook Reservoir was created in 1838 to provide extra water supplies at a time of increasing trade on the canal. It was situated in a small side valley branching off the River Goyt valley, just south of the canal’s Whaley Bridge terminus, which it fed via a feeder culvert. Its water came from the Todd Brook and other small streams; a bywash channel was built around the north side of the lake to carry surplus water from the brook around the dam, and an overflow spillway at the north end of the dam would come into operation if the reservoir was full. The dam was typical of the era, being built of earth around a clay core, albeit it was higher than many – it is reported that at 79ft it was the tallest canal reservoir dam to date.

After 130 years of service supplying the canal, with various works carried out at different times to deal with problems of leakage and subsidence, in 1970, Toddbrook gained another spillway. This followed damage to the existing spillway following high rainfall, which led to it being regarded as inadequate. In line with similar actions affecting a number of other non-canal dams, an Inspecting Engineer recommended adding a second spillway.

Close-up of work on the two turrets forming part of the stilling basin structure

The existing spillway would continue to function as what’s known as the ‘primary spillway’ in reservoir jargon, coping with all the surplus water in normal conditions. The new spillway would be an ‘auxiliary spillway’, built with a higher weir level so that it would only come into use in extreme conditions, when the primary spillway was inadequate to cope with very high water volumes.

It took the form of a concrete weir along the top of part of the dam, carrying the water into a spillway constructed from concrete panels laid on the downstream face of the dam.

In fact, it was only needed something like five times in its half century in service. Come 2019, and those “extreme conditions” arrived in a big way. Two separate abnormal rainfall events (both in the “once every 100 years” ballpark) fell within a very short space of time. The reservoir filled right up, the primary spillweir couldn’t cope, the auxiliary spillway was called upon to carry out its emergency function – and failed spectacularly. Under the deluge of water coming over the dam the north side of the concrete-built spillway broke up with severe damage to the concrete slabs, dam infill material from underneath them was washed out, and there were serious fears that the dam could collapse. A full-scale emergency was declared, more than 1,500 residents in Whaley Bridge, immediately down the valley from the dam, were evacuated for six days, and emergency action was taken involving an RAF helicopter lifting in large numbers of bags of material to stabilise the situation, while pumps were brought in to draw down the water level in the reservoir to a safe level.

Clearly some major rebuilding would be needed. But first, studies and reports would be needed to identify what had gone wrong, and how a repeat could be avoided in the future. And in the meantime, it would be necessary to guard against any further extreme weather events which happened before the rebuilding could take place. For this purpose, a set of eleven high-capacity portable pumps and associated hoses were set up, with a total pumping capacity of some 2500 litres per second, to keep the water level down in the case of heavy rainfall. The water is normally kept down at 12m below weir level, typically requiring just one pump running. As water level rises after rain, an extra pump will start up for every 150mm of rise.

Independent reports into the incident were commissioned by both CRT and Defra. And whilst they may have differed in the detail when it came to adequacy of maintenance, quality of original construction and other matters, they both identified that the root of the problem was that it was a fundamentally inadequate design of spillway. In particular the lack of a ‘cut-off’ (an impenetrable barrier) between the weir crest and the clay core of the dam allowed water to work its way under the spillway’s concrete slabs and gaps to develop, making it susceptible to failure.

Another load of concrete arrives and is lifted into place – altogether the work will take some 5,000 cubic metres

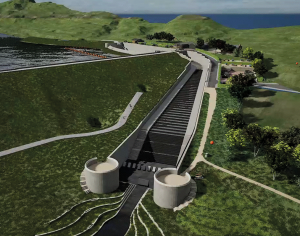

These findings in turn led to a decision that the auxiliary spillweir would not be replaced by a new one in the same location. From various options considered, the decision was made to build a single new spillway at the north end of the dam. This would replace both the original 1830s primary spillway and the 1970 auxiliary spillway with a single high-capacity structure. And what I can see from my vantage point on the dam is two features of this spillway.

At the north end of the dam, the original primary spillway has been removed and the new overflow weir structure is under construction – its main components are the actual weir crest and the ‘tumble bay’ – the area into which the water running over the weir falls. From there it will be carried down the spillway chute, descending past the end of the dam to reach a ‘stilling basin’’. This hydrological structure is designed to reduce the speed of the water and dissipate a lot of its energy – in technical terms it changes it from ‘laminar flow’ to ‘turbulent flow’. This is done by changing the profile, depth and gradient of the chute – and the two circular ‘turrets’, one each side of the channel to constrict its width, are part of this structure. They’re also going to be a ‘feature’ of the finished design, decorated with artwork created as part of a community art project by local artist Tom Edwards. But they’re an important part of the hydrological design, enabling overflow water to be safely discharged, ultimately into the River Goyt.

All of this construction has to take place in a particular sequence, allowing for the possibility that at any time during the work, another flood could happen. First, the bywash channel was diverted to take surplus water from the Todd Brook around the new works. Next, the new channel bypassing the dam was built, but dammed by a line of heavy-duty steel piles across it, braced in place by large steel beams, to ensure that any water is kept out while the lower section of the spillway including the stilling basin is completed (a temporary arrangement allows any surplus water from heavy rain to overflow into the diverted bywash). Once the stilling basin has been completed, the piles damming the new channel can be removed. With the new channel available to take away surplus water, it will then be safe to carry out the actual repairs to the dam, including completely removing the remains of the failed spillway, and grassing over the dam (as it was before the spillway was built). Only then can the weir at the head of the new spillway be completed to its final height. Actually, to two different heights along its length – one part will function as the ‘primary’ weir, and the other as the ‘auxiliary’ weir after heavy rain.

Artist’s impressions of the finished structure

It’s a massive project – Dilwyn Parry quotes some statistics: 1000 steel piles, 500 concrete piles, 5000 cubic metres of concrete, 700 tonnes of steel reinforcing. And its an expensive one too: the total direct cost is around £30m, but including all the extras such as planning, temporary work, dealing with the initial emergency and so on, it probably totals nearer £50m. It’s taken around 20 percent of the total regional CRT budget over five to six years.

CRT anticipates that construction work will be largely completed by the end of 2024, with the aim being to have it finished by summer 2025. This will be followed by dismantling of the construction site, landscaping work, building a new sailing club (the old one was in the way of the new spillway), bringing the public park back to public use, and the reservoir resuming its function supplying one third of the water needed for the Peak Forest and Macclesfield summit levels during 2025, and the lock opening hours restrictions which have limited use of these canals for the last five years can be lifted.

It should be capable of dealing not just with ‘once in 100 years’ type events, but a truly cataclysmic ‘once in 30,000 years’ deluge. As CRT’s Matthew Symonds told Canal Boat, “There won’t be much else left, but there will be a lovely reservoir.”

As featured in the October 2024 issue of Canal Boat. Buy the issue here

As featured in the October 2024 issue of Canal Boat. Buy the issue here